Ordering Process

Pleated inserts have always been the key to taking your project to the next level. The problem is that it takes a lot of time, energy, and math! Thats what we are trying to fix. Our CNC Stitching service works for you. You send in the materials and tell us what you want and we make it happen!

|

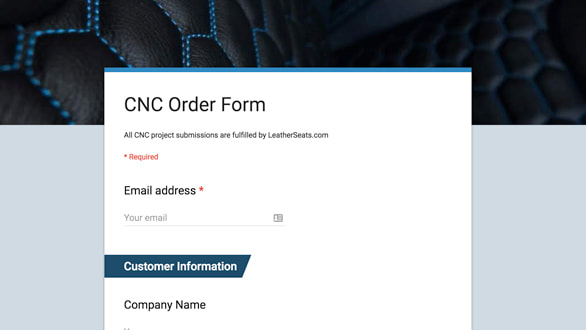

STEP 1

Fill out the CNC Order Form and we will go over the details of your project. You can choose use either the materials that we sell or you can provide your own. The form also gives you the design options available and room for any addition information that we may need. Once your order is submitted, a price quote will be given to you based on the pattern you choose and how many panels you will be need for your project. |

|

STEP 2

Prepare the materials. If you are sending us pre-cut materials do not cut the panels before speaking with us. The panel will shrink as the stitch design is being quilted so it is important for us to understand the final dimensions before any materials are cut. We then mount the material to our scrim backed quilting foam and secured to one of our custom designed quilting frames to begin the CNC stitching process. |

|

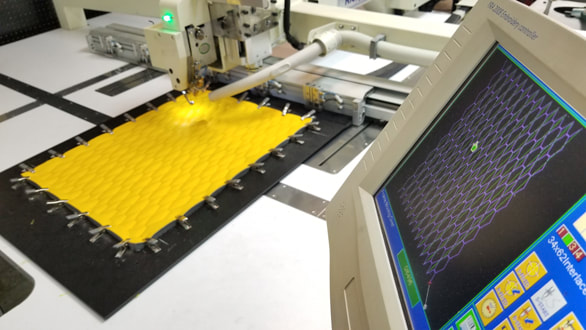

STEP 3

Stitching your design! Our CNC quilting machine has a sewing field of 47" x 31". The machine's stationary sewing arm stitches at variable speeds as the servo motors move the stitching frame continuously in the X and Y axis following a vector based digital stitch path. Because our structural quilting frame is driven by CNC servo motors we can achieve incredible stitch quality on complex designs with highly reproducible results. |

|

STEP 4

Shipping your quilting panels! Depending on the specific application, we clean, trim and prep the quilted panels for shipping. The panels will arrive to you ready to be used for your specific project. Be sure to email us pictures of your finished projects! We love to see how talented trimmers across the globe are able to unleash their creativity by leveraging the latest in CNC stitching technology! #LSPrimeCNC |